-

Carbon Steel Pipe

LSAW Steel Pipe

SSAW Steel Pipe

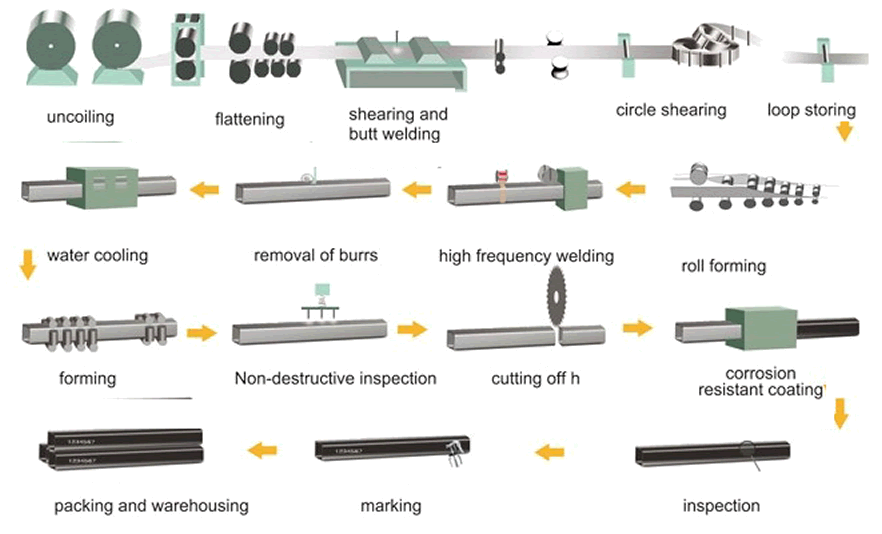

ERW Steel Pipe

Rolled And Welded Pipe

-

Seamless steel pipe

Seamless Steel Pipe

APL5L Line Pipe

Boiler steel pipe

Finned Tube

Stainless Steel Screen Pipe

Pin Tube

-

Oilfield Tubular Goods

Casing and Tubing steel pipe

Slotted Pipe

Drill Pipe And Drill Collar

Pup Joint

Coupling

-

Alloy Steel Pipe

Alloy Seamless Steel Pipe

Alloy Welded Steel Pipe

Nickel Alloy Pipe

Monel Alloy Pipe

Inconel Alloy Pipe

Titanium Pipe

-

Coated Steel Pipe

FBE Coated Pipe

Epoxy Coated Pipe

3LPE Coated Pipe

Concrete Coated Pipe

Galvanized Steel Pipe

-

Stainless Steel Pipe

Stainless Steel Seamless Pipe

Stainless Steel Welded Pipe

Stainless Hollow Section

Stainless Rectangular Hollow Section

Stainless Steel Plate

-

Pipe Fittings

Flanges

Elbow

Tee

Reducer

-

Structural steel

Piling Pipe

Steel Sheet Pile

H Section

H/U/I Beam

Flat & Angle Bar

C Channel

-

Steel Plate

Carbon Steel Plate

Stainless Steel Plate

-

Hollow Section

Hollow Section

Square steel pipe

Rectangular steel pipe

Circular hollow section

-

Valve

Gate Valve

Gate Valve

Check Valve

Globe Valve

Plug valve

ball valve

-

Steel Structure Fabrication

Steel Structural Support Frames Backbone

Box Steel Components Steel Structure

Sustainable Prefab Steel

Steel Box Section Structural Members

Structural Steel Roof Truss Systems

Stud Welded Steel Column Structure

English

English Español

Español

Tel : +86-18565811709

Tel : +86-18565811709 Email :

Email :