Description

Concentric Reducers (CR)

Concentric reducers are used to transition between pipes of the same diameter. They come in both steel and cast iron, and they can be found in a variety of sizes, including 2-inch, 3-inch, 4-inch and 6-inch. They are also known as male reducers because their outside diameter is larger than the inside diameter of their mating part (in this case a female adapter).

Eccentric Reducers (ER)

Eccentric reducers are used to transition between pipes of different diameters. The eccentric design allows for the joining of a pipe with an inside diameter that is larger than another.

Standard: ASME B16.9, DIN2615, JIS B2312, ASME B16.11

Material: Carbon Steel ASTM A234 WPB,

Alloy Steel ASTM A234 WP1, WP5, WP9, WP11, WP22

Stainless Steel ASTM A403 304/316

Types: Equal and Reducing

Size Range: 1/2″ to 24″

Wall thickness: Sch10, Sch40, Sch80

Pressure Rations: 3000#, 6000#, 9000#

Concentric Pipe Reducer and Eccentric Pipe Reducer Dimensions are covered in ASME B16.9. Refer to the table given below for the size 1/2″ to 24″.

Specification

Specification

|

NPS1

|

NPS2

|

OD1

|

OD2

|

H

|

|

3/4

|

1/2

|

26.7

|

21.3

|

38

|

|

3/4

|

3/8

|

26.7

|

17.3

|

38

|

|

1

|

3/4

|

33.4

|

26.7

|

51

|

|

1

|

1/2

|

33.4

|

21.3

|

51

|

|

1-1/4

|

1

|

42.2

|

33.4

|

51

|

|

1-1/4

|

3/4

|

42.2

|

26.7

|

51

|

|

1-1/4

|

1/2

|

42.2

|

21.3

|

51

|

|

1-1/2

|

1-1/4

|

48.3

|

42.2

|

64

|

|

1-1/2

|

1

|

48.3

|

33.4

|

64

|

|

1-1/2

|

3/4

|

48.3

|

26.7

|

64

|

|

1-1/2

|

1/2

|

48.3

|

21.3

|

64

|

|

2

|

1-1/2

|

60.3

|

48.3

|

76

|

|

2

|

1-1/4

|

60.3

|

42.2

|

76

|

|

2

|

1

|

60.3

|

33.4

|

76

|

|

2

|

3/4

|

60.3

|

26.7

|

76

|

|

NPS1

|

NPS2

|

OD1

|

OD2

|

H

|

|

2-1/2

|

2

|

73.0

|

60.3

|

89

|

|

2-1/2

|

1-1/2

|

73.0

|

48.3

|

89

|

|

2-1/2

|

1-1/4

|

73.0

|

42.2

|

89

|

|

2-1/2

|

1

|

73.0

|

33.4

|

89

|

|

3

|

2-1/2

|

88.9

|

73.0

|

89

|

|

3

|

2

|

88.9

|

60.3

|

89

|

|

3

|

1-1/2

|

88.9

|

48.3

|

89

|

|

3

|

1-1/4

|

88.9

|

42.2

|

89

|

|

3-1/2

|

3

|

101.6

|

88.9

|

102

|

|

3-1/2

|

2-1/2

|

101.6

|

73.0

|

102

|

|

3-1/2

|

2

|

101.6

|

60.3

|

102

|

|

3-1/2

|

1-1/2

|

101.6

|

48.3

|

102

|

|

3-1/2

|

1-1/4

|

101.6

|

42.2

|

102

|

|

4

|

3-1/2

|

114.3

|

101.6

|

102

|

|

4

|

3

|

114.3

|

88.9

|

102

|

|

NPS1

|

NPS2

|

OD1

|

OD2

|

H

|

|

4

|

2-1/2

|

114.3

|

73.0

|

102

|

|

4

|

2

|

114.3

|

60.3

|

102

|

|

4

|

1-1/2

|

114.3

|

48.3

|

102

|

|

5

|

4

|

141.3

|

114.3

|

127

|

|

5

|

3-1/2

|

141.3

|

101.6

|

127

|

|

5

|

3

|

141.3

|

88.9

|

127

|

|

5

|

2-1/2

|

141.3

|

73.0

|

127

|

|

5

|

2

|

141.3

|

60.3

|

127

|

|

6

|

5

|

168.3

|

141.3

|

140

|

|

6

|

4

|

168.3

|

114.3

|

140

|

|

6

|

3-1/2

|

168.3

|

101.6

|

140

|

|

6

|

3

|

168.3

|

88.9

|

140

|

|

6

|

2-1/2

|

168.3

|

73.0

|

140

|

|

8

|

6

|

219.1

|

168.3

|

152

|

|

8

|

5

|

219.1

|

141.3

|

152

|

|

NPS1

|

NPS2

|

OD1

|

OD2

|

H

|

|

8

|

4

|

219.1

|

114.3

|

152

|

|

8

|

3-1/2

|

219.1

|

101.6

|

152

|

|

10

|

8

|

273.0

|

219.1

|

178

|

|

10

|

6

|

273.0

|

168.3

|

178

|

|

10

|

5

|

273.0

|

141.3

|

178

|

|

10

|

4

|

273.0

|

114.3

|

178

|

|

12

|

10

|

323.8

|

273.0

|

203

|

|

12

|

8

|

323.8

|

219.1

|

203

|

|

12

|

6

|

323.8

|

168.3

|

203

|

|

12

|

5

|

323.8

|

141.3

|

203

|

|

14

|

12

|

355.6

|

323.8

|

330

|

|

14

|

10

|

355.6

|

273.0

|

330

|

|

14

|

8

|

355.6

|

219.1

|

330

|

|

14

|

6

|

355.6

|

168.3

|

330

|

|

16

|

14

|

406.4

|

355.6

|

356

|

|

NPS1

|

NPS2

|

OD1

|

OD2

|

H

|

|

16

|

12

|

406.4

|

323.8

|

356

|

|

16

|

10

|

406.4

|

273.0

|

356

|

|

16

|

8

|

406.4

|

219.1

|

356

|

|

18

|

16

|

457.0

|

406.4

|

381

|

|

18

|

14

|

457.0

|

355.6

|

381

|

|

18

|

12

|

457.0

|

323.8

|

381

|

|

18

|

10

|

457.0

|

273.0

|

381

|

|

20

|

18

|

508.0

|

457.0

|

508

|

|

20

|

16

|

508.0

|

406.4

|

508

|

|

20

|

14

|

508.0

|

355.6

|

508

|

|

20

|

12

|

508.0

|

323.8

|

508

|

|

22

|

20

|

559.0

|

508.0

|

508

|

|

22

|

18

|

559.0

|

457.0

|

508

|

|

22

|

16

|

559.0

|

406.4

|

508

|

|

22

|

14

|

559.0

|

355.4

|

508

|

|

NPS1

|

NPS2

|

OD1

|

OD2

|

H

|

|

24

|

22

|

610.0

|

559.0

|

508

|

|

24

|

20

|

610.0

|

508.0

|

508

|

|

24

|

18

|

610.0

|

457.0

|

508

|

|

24

|

16

|

610.0

|

406.4

|

508

|

|

26

|

24

|

660.0

|

610.0

|

610

|

|

26

|

22

|

660.0

|

559.0

|

610

|

|

26

|

20

|

660.0

|

508.0

|

610

|

|

26

|

18

|

660.0

|

457.0

|

610

|

|

28

|

26

|

711.0

|

660.0

|

610

|

|

28

|

24

|

711.0

|

610.0

|

610

|

|

28

|

20

|

711.0

|

508.0

|

610

|

|

28

|

18

|

711.0

|

457.0

|

610

|

|

30

|

28

|

762.0

|

711.0

|

610

|

|

30

|

26

|

762.0

|

660.0

|

610

|

|

30

|

24

|

762.0

|

610.0

|

610

|

|

NPS1

|

NPS2

|

OD1

|

OD2

|

H

|

|

30

|

20

|

762.0

|

508.0

|

610

|

|

32

|

30

|

813.0

|

762.0

|

610

|

|

32

|

28

|

813.0

|

711.0

|

610

|

|

32

|

26

|

813.0

|

660.0

|

610

|

|

32

|

24

|

813.0

|

610.0

|

610

|

|

34

|

32

|

864.0

|

813.0

|

610

|

|

34

|

30

|

864.0

|

762.0

|

610

|

|

34

|

26

|

864.0

|

660.0

|

610

|

|

34

|

24

|

864.0

|

610.0

|

610

|

|

36

|

34

|

914.0

|

864.0

|

610

|

|

36

|

32

|

914.0

|

813.0

|

610

|

|

36

|

30

|

914.0

|

762.0

|

610

|

|

36

|

26

|

914.0

|

660.0

|

610

|

|

36

|

24

|

914.0

|

610.0

|

610

|

|

38

|

36

|

965.0

|

914.0

|

610

|

|

NPS1

|

NPS2

|

OD1

|

OD2

|

H

|

|

38

|

34

|

965.0

|

864.0

|

610

|

|

38

|

32

|

965.0

|

813.0

|

610

|

|

38

|

30

|

965.0

|

762.0

|

610

|

|

38

|

28

|

965.0

|

711.0

|

610

|

|

38

|

26

|

965.0

|

660.0

|

610

|

|

40

|

38

|

1016.0

|

965.0

|

610

|

|

40

|

36

|

1016.0

|

914.0

|

610

|

|

40

|

34

|

1016.0

|

864.0

|

610

|

|

40

|

32

|

1016.0

|

813.0

|

610

|

|

40

|

30

|

1016.0

|

762.0

|

610

|

|

42

|

40

|

1067.0

|

1016.0

|

610

|

|

42

|

38

|

1067.0

|

965.0

|

610

|

|

42

|

36

|

1067.0

|

914.0

|

610

|

|

42

|

34

|

1067.0

|

864.0

|

610

|

|

42

|

32

|

1067.0

|

813.0

|

610

|

|

NPS1

|

NPS2

|

OD1

|

OD2

|

H

|

|

42

|

30

|

1067.0

|

762.0

|

610

|

|

44

|

42

|

1118.0

|

1067.0

|

610

|

|

44

|

40

|

1118.0

|

1016.0

|

610

|

|

44

|

38

|

1118.0

|

965.0

|

610

|

|

44

|

36

|

1118.0

|

914.0

|

610

|

|

46

|

44

|

1168.0

|

1118.0

|

711

|

|

46

|

42

|

1168.0

|

1067.0

|

711

|

|

46

|

40

|

1168.0

|

1016.0

|

711

|

|

46

|

38

|

1168.0

|

965.0

|

711

|

|

48

|

46

|

1219.0

|

1168.0

|

711

|

|

48

|

44

|

1219.0

|

1118.0

|

711

|

|

48

|

42

|

1219.0

|

1067.0

|

711

|

|

48

|

40

|

1219.0

|

1016.0

|

711

|

|

NPS1

|

NPS2

|

OD1

|

OD2

|

H

|

Standard

Stainless Steel Reducer : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L.

Carbon Steel Reducer : ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel Reducer : ASTM A420 WPL3, A420 WPL6.

Alloy Steel Reducer : ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91.

Duplex Steel Reducer : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462.

Titanium Alloy Reducer : ASTM B363 WPT2, WPT3, WPT7, WPT9, WPT11

Nickel Alloy Reducer : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276).

Copper Alloy Reducer: ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30)

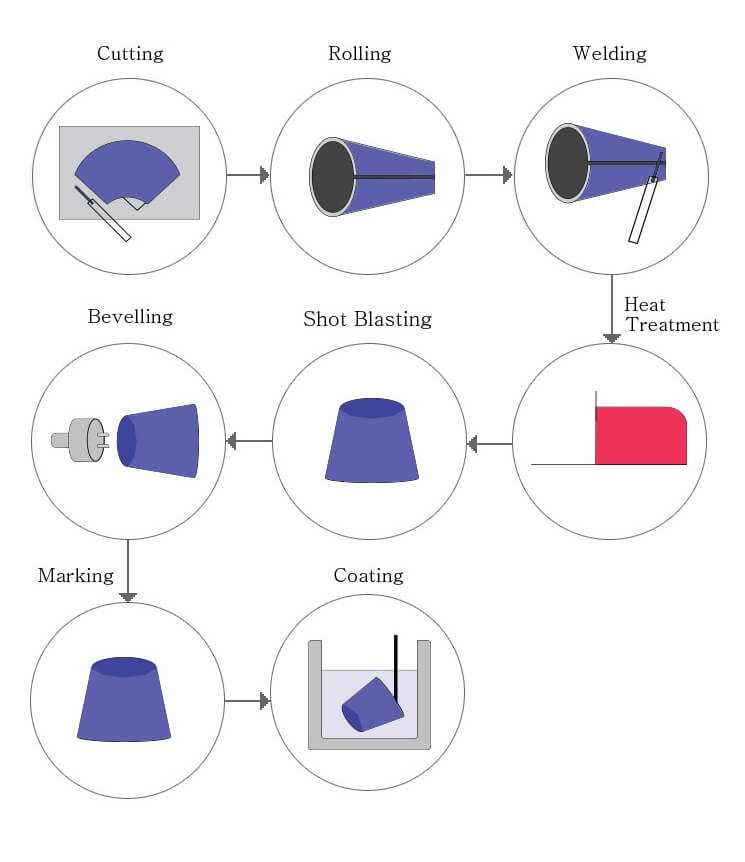

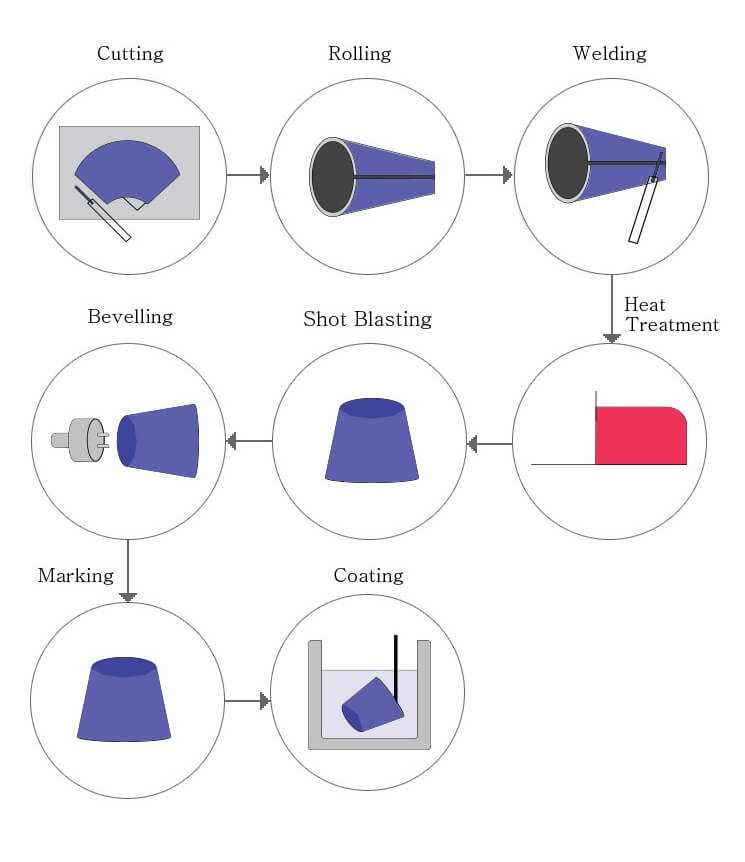

Process

Packing

Standard

Stainless Steel Reducer : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L.

Carbon Steel Reducer : ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel Reducer : ASTM A420 WPL3, A420 WPL6.

Alloy Steel Reducer : ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91.

Duplex Steel Reducer : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462.

Titanium Alloy Reducer : ASTM B363 WPT2, WPT3, WPT7, WPT9, WPT11

Nickel Alloy Reducer : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276).

Copper Alloy Reducer: ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30)

English

English Español

Español

Tel : +86-18565811709

Tel : +86-18565811709 Email :

Email :